Electrical installation condition reporting:

Classification Codes for domestic and similar electrical installations

The aim of this Guide is to provide practical guidance for skilled persons competent in electrical inspection and testing on the use of the Classification Codes that need to be attributed to each observation recorded during the periodic inspection and testing of an electrical installation for the benefit of the person ordering the report.The guidance is limited to the range of observations that are likely to be associated with domestic and similar electrical installations. It takes into account the publication of BS 7671.

Quick Links

Introduction

Electrical Installation Condition Report

Purpose of periodic inspection, testing and reporting

Examples of the use of Classification CodesContributors and supporters

Introduction

Every electrical installation deteriorates with use and time. Therefore, if the safety of the users is not to be put at risk, it is important that every installation is periodically inspected and tested by a competent person. Indeed, it is recommended in BS 7671 that every electrical installation is subjected to periodic inspection and testing (Regulation 135.1 refers).The inspection and testing should be carried out at appropriate intervals in order to determine what, if anything, needs to be done to maintain the installation in a safe and serviceable condition.Inspecting a socket-outletThe results of the inspection and testing need to be detailed clearly in a report. Any observed damage, deterioration, defects, dangerous conditions and non-compliances with the requirements of the current edition of BS 7671 that may give rise to danger should be recorded (Regulation 653.2) and appropriately classified for remedial action.It should be borne in mind that, as stated in the introduction to BS 7671, existing installations that have been installed in accordance with earlier editions of BS 7671 may not comply with the current edition in every respect, but this does not necessarily mean that they are unsafe for continued use or require upgrading.

Inspecting a socket-outlet

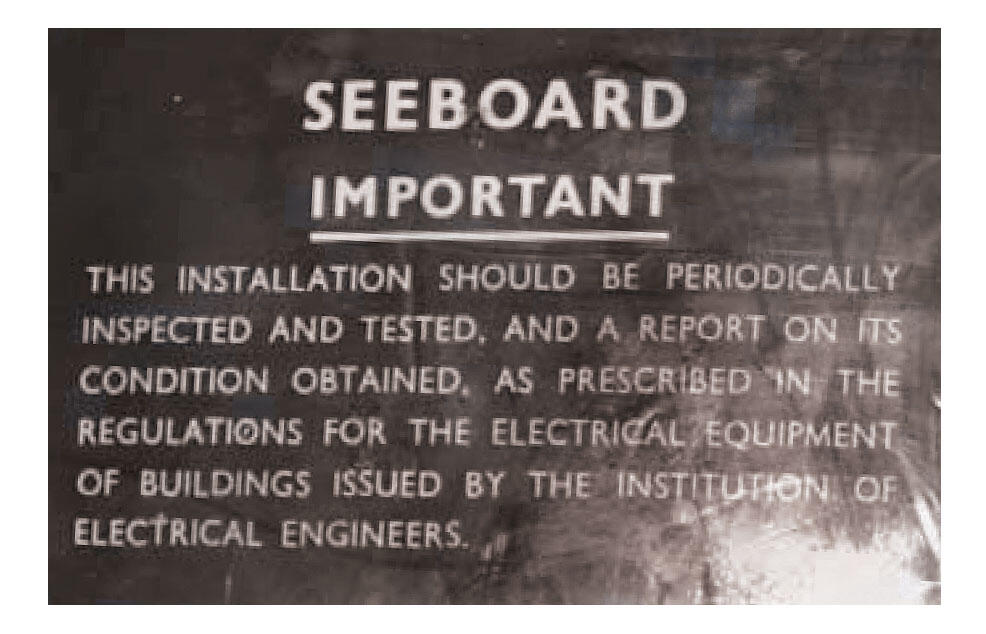

A typical periodic inspection notice for an older installation

Electrical Installation Condition Report

As its title indicates, this is a report and not a certificate. It provides an assessment of the current in-service condition of an electrical installation against the requirements of the edition of BS 7671 current at the time of the inspection, irrespective of the age of the installation.The report is primarily for the benefit of the person ordering the work and of persons subsequently involved in additional or remedial work, or further inspections. The report may be required for one or more of a variety of reasons, each of which may impose particular requirements or limitations on the inspection and testing.The report is required to include details of the extent of the installation and of any limitations of the inspection and testing (Regulation 653.2) including the reasons for any such limitations and the name of the person with whom those limitations were agreed. It should be noted that the greater the limitations applying, the lesser is the scope of the inspection and testing carried out, and hence the value of the report is correspondingly diminished. The report is also required to include a record of the inspection and the results of testing.The report provides a formal declaration that, within the agreed and stated limitations, the details recorded, including the observations and recommendations, and the completed schedules of inspection and test results, give an accurate assessment of the condition of the electrical installation at the time it was inspected

Purpose of periodic inspection, testing and reporting

The main purpose of periodic inspection and testing is to detect so far as is reasonably practicable, and to report on, any factors impairing or likely to impair the safety of an electrical installation.

A typical periodic inspection notice for an older installation

Electrical installations in poor condition present risks of fire as well as electric shockThe aspects to be covered include all of the following:

• Safety of persons against the effects of electric shock and burns

• Protection against damage to property by fire and heat arising from an installation defect

• Confirmation that the installation is not damaged or deteriorated so as to impair safety

• Identification of non-compliances with the current edition of BS 7671, or installation defects, which may give rise to danger.

Electrical installations in poor condition present risks of fire as well as electric shock

Examples of the use of Classification Codes

It is entirely a matter for the competent person conducting the inspection to decide on the Classification Code to be attributed to an observation. The inspector’s own judgement as a competent person should not be unduly influenced by the person ordering the work. The person(s) signing the report are fully responsible for its content and accuracy.

The following examples are not exhaustive.

| Category | Code | Description |

|---|---|---|

| Access to Live Parts | 1 | A fuse carrier or circuit-breaker is missing from a consumer unit and a suitable and securely fitted blanking piece is not in its place - exposed live parts accessible to touch |

| Access to Live Parts | 1 | An accessory is badly damaged - exposed live parts accessible to touch |

| Access to Live Parts | 1 | Live conductors (line and/or neutral) have no (or damaged) insulation - exposed live parts accessible to touch |

| Access to Live Parts | 1 | Terminations or connections have no (or damaged) barriers or enclosures exposed live parts accessible to touch |

| Access to Live Parts | 1 | Conductive parts have become live as the result of a fault |

| Polarity | 1 | Incorrect polarity at Origin |

| Earthing | 2 | Absence of a reliable and effective means of earthing for the installation |

| Small Sample | 3 | Just an example of many |

Thanks to the following organisations

Electrical Safety First is indebted to the following organisations for their contribution and/or support to the development of this Guide:

Thank you

Lorem ipsum dolor odio ut sem. Tempus iaculis urna lacus laoreet vel pharetra.